Crochet a shawl for spring

A perfect spring wrap for chilly evenings, morning strolls or even as a beautiful baby blanket!

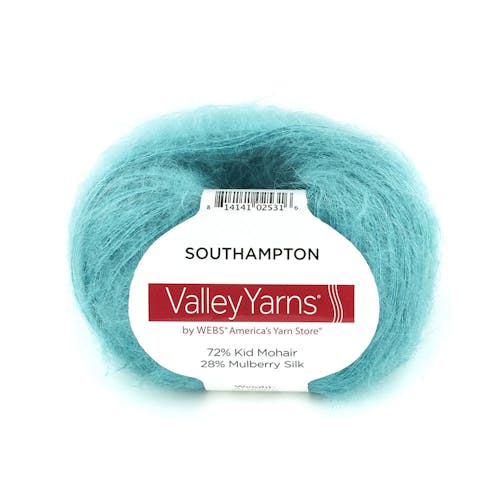

Find the yarns you love

Ready for your next project? Browse our huge range of knitting and crochet yarn. Find great quality wool from all your favourite yarn brands.

Patterns

Shoutout to our amazing designers!

Discover brands from the LoveCrafts family

Welcome to LoveCrafts, your home to shop, share and dream in crafts. Makers, discover thousands of crochet patterns and knitting patterns to inspire your next project. Stock up your yarn supply with Lion Brand, Rowan, Paintbox Yarns and more. Explore wonderful fibres like oh-so-warm alpaca yarn and merino wool, or find yarns by weight, from classic aran and worsted weight to super chunky yarn. Fill up your fabric and stitching stash with the latest fabrics, cross stitch kits and embroidery supplies you need too. What are you waiting for? Grab your needles, hooks, and hoops and start making!